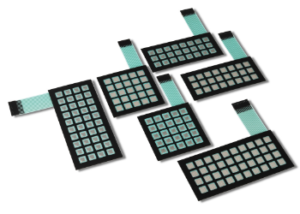

Not all keyboards classify under the type of mechanical switch or flat-panel membrane. There’s also a hybrid of both that sustains the combination of their respective elements. Named a dome switch, it utilises two circuit boards under a flexible keypad opting for metal or polyurethane-shaped domes. Hence, they are termed ‘dome-switches’.

What is a dome switch?

Dome switches are a particular type of electrical switch identified using silicone, rubber or metal materials to make domes above the primary circuit.

Metal dome switches are often chosen over their silicone or rubber counterparts due to the crisp tactile feedback they give. After pressing a metal dome switch, it answers with positive tactile input. This feedback is crucial in reducing typing mistakes, as it illuminates the user that their keypress was appropriately registered.

Dome switches can be planned or designed in many materials, including silicone, elastic, metal and polyurethane. When metal is utilised, dome switches offer a prestigious degree of tactile feedback, a magnetic element not found in numerous other switch designs. Besides, dome switches support plating, providing a prominent degree of customisation. These factors contribute to countless organisations and professionals’ usage of dome switches.

Hence, its life span is the best advantage of opting for a dome switch. Like all switches, dome switches are vulnerable to failure and degradation. However, this is not something that happens instantly or overnight. In opposition to that, a dome switch requires a long time before any observable degradation occurs.

Hence, fortunately, this is a region wherein dome switches excel. And thus, it can be inferred that it’s conventional for a metal dome to switch to last for more than 5 million cycles. This implies that you can press or, in any case, activate the switch more than 5 million times. And at times, the metal dome switches can sustain for much longer, particularly when used in an apt away, like in a clean environment.

Additionally, dome switches are accessible in endless sizes and dozens of shapes, and No matter what your application is, odds are there’s a dome switch to meet your needs.

How does a dome light switch work?

If the switch is set to ‘DOOR’, at the point when an entryway is opened, and ignition key chamber lights are lit in a fade-in or blur way, within seconds and after that, the switch gets switched off while becoming dim, when the timer it holds gets terminated. In case the light is kept on for 20 minutes with the entryway open, it is switched off on its own automatically.

Subsequently, to turn off a dome light, open the door, and find the switch. Also, search for an active switch, stuck or trapped in an open position in case any. After that, you will have to manually press each of the switches to see if the light is being deactivated or not.

In case the light is constantly on, it may be so that someone has turned the switch from the general “auto” position to “on” and perhaps left it as it is over there. Normally, the switch should be in the middle position.

In addition, there are some frequently faced problems with dome lights, and these include blown fuses and burnt-out bulbs. If you face any such issue, you should:

-

-

-

-

-

-

- Assess the dome light switch. This should be done in front of the fixture or apparatus of the dome light.

- If the dome light still does not work, replace the bulb.

- If replacing the bulb also does not work, replace the fuse.

-

-

-

-

-

Difference between dome switch and mechanical:

As seen above, dome switches are a hybrid of mechanical switches and flat-panel membranes. They constitute two circuit board traces under a silicone or rubber keypad using either polyurethane-formed domes or metal “dome” switches. The metal dome switches are made of stainless steel bits that, when compressed or compacted, give the user crisp, positive tactile feedback.

On the other hand, when we consider a mechanical-switch keyboard, each key on a mechanical-switch console holds a complete switch under it. Each switch is made out of a spring, a housing, and a stem, and in several instances, it may also include various other parts like a different tactile leaf or perhaps a click bar.

Their switches come in three variations:

-

-

-

- “linear” with strenuous unhindered resistance,

- “tactile” with a non-discernible bump, and

- “clicky” with an audible click and a bump too.

-

-

Depending on the opposition of the spring, the key requires various measures of pressure to propel and to reach as far down as possible. The state of the stem, as well as the layout of the switch lodging, shifts the switch’s travel distance and actuation distance.

The sound can be modified by the case’s material, plate, case, keycap profile, lubrication, and even adjusting the singular switch. These modifications, changes or “mods” incorporate applying lubrication to decrease friction inside the actual switch, embedding “switch films” to diminish wobble, trading out the spring inside to adjust the opposition of the actual switch and numerous more. In addition, mechanical consoles consider the expulsion and replacement of keycaps with a typical stem type.

Close by the mechanical console switch is the stabiliser, which upholds longer keys, for example, the “enter”, “spacebar”, “backspace”, and “shift” keys. Although these are not as various as switches, they come in distinct sizes. These various sizes are intended for keyboards that are longer than typical. Like a mechanical keyboard switch, the stabiliser can be changed to modify the sound and feel of these specific keys.

Lubricant can be utilised to lessen the clatter of the metal wire that forms a stabiliser. Besides, incorporating padding in the “housing” of the stabiliser will diminish this rattle and improve acoustics.

Furthermore, the biggest difference between a dome switch and mechanical consoles is that mechanical switches commonly have a more extended life expectancy than vault or dome switches.

Please contact us for any enquiry

Can I simply say what a comfort to find somebody that actually knows what they are talking about on the net. You definitely realize how to bring a problem to light and make it important. More people have to check this out and understand this side of your story. I cant believe you are not more popular because you certainly have the gift.

Excellent blog post. I definitely appreciate this website. Continue the good work!

I was excited to uncover this great site. I need to to thank you for your time for this particularly wonderful read!! I definitely enjoyed every part of it and I have you book marked to check out new stuff in your web site.

I have to thank you for the efforts youve put in writing this blog. Im hoping to check out the same high-grade blog posts by you later on as well. In fact, your creative writing abilities has encouraged me to get my own website now 😉

Good post. I learn something new and challenging on sites I stumbleupon every day. It will always be helpful to read content from other writers and practice something from their websites.

I cherished as much as you’ll receive carried out right here. The comic strip is attractive, your authored material stylish. nevertheless, you command get got an edginess over that you want be turning in the following. ill undoubtedly come further earlier again since exactly the same just about a lot regularly within case you defend this hike.

I enjoy forgathering utile info, this post has got me even more info! .

I do not even understand how I ended up here, but I assumed this publish used to be great

You’re so awesome! I don’t believe I have read a single thing like that before. So great to find someone with some original thoughts on this topic. Really.. thank you for starting this up. This website is something that is needed on the internet, someone with a little originality!

I loved as much as youll receive carried out right here The sketch is attractive your authored material stylish nonetheless you command get bought an nervousness over that you wish be delivering the following unwell unquestionably come more formerly again as exactly the same nearly a lot often inside case you shield this hike

I am grateful that you shared this blog post with me.

Somebody essentially help to make significantly articles Id state This is the first time I frequented your web page and up to now I surprised with the research you made to make this actual post incredible Fantastic job

Howdy very cool website!! Guy .. Excellent .. Amazing .. I’ll bookmark your site and take the feeds alsoKI’m happy to search out a lot of helpful information here in the put up, we want develop extra strategies in this regard, thank you for sharing. . . . . .

I thought you did a great job here. The language is excellent and the picture is tasteful, but you come across as nervous about what you might say next. If you preserve this walk, I have no doubt that I will return more often.

It was great seeing how much work you put into it. Even though the design is nice and the writing is stylish, you seem to be having trouble with it. I think you should really try sending the next article. I’ll definitely be back for more of the same if you protect this hike.

I was recommended this website by my cousin I am not sure whether this post is written by him as nobody else know such detailed about my trouble You are amazing Thanks

I just could not leave your web site before suggesting that I really enjoyed the standard information a person supply to your visitors Is gonna be again steadily in order to check up on new posts

Thank you I have just been searching for information approximately this topic for a while and yours is the best I have found out so far However what in regards to the bottom line Are you certain concerning the supply

Nice blog here Also your site loads up fast What host are you using Can I get your affiliate link to your host I wish my web site loaded up as quickly as yours lol

Thank you I have just been searching for information approximately this topic for a while and yours is the best I have found out so far However what in regards to the bottom line Are you certain concerning the supply

This website online is really a walk-by for all of the info you wished about this and didn’t know who to ask. Glimpse right here, and also you’ll undoubtedly uncover it.

Thank you for any other informative web site. Where else could I get that kind of info written in such an ideal approach? I’ve a challenge that I am simply now operating on, and I’ve been on the glance out for such information.

I see something truly special in this site.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Yes, please go through this blog link: https://protolab.in/what-is-tactile-and-non-tactile-membrane-keypad-switches/ for more details

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I’m impressed, I have to say. Really not often do I encounter a weblog that’s both educative and entertaining, and let me let you know, you might have hit the nail on the head. Your concept is outstanding; the issue is one thing that not enough persons are speaking intelligently about. I’m very comfortable that I stumbled throughout this in my search for one thing relating to this.

I am continuously looking online for ideas that can aid me. Thx!

Hello! I could have sworn I’ve been to this blog before but after browsing through some of the post I realized it’s new to me. Anyways, I’m definitely happy I found it and I’ll be book-marking and checking back frequently!