Printed Electronics

Bringing surfaces to life.

Introduction To Printed Electronics

- Printed Electronics represents an emerging area of printing electrical circuits on flexible substrates.

- This technology can bypass traditional expensive and inflexible silicon-based electronics.

- They are being used on numerous devices and are made using high-end printing approaches.

- From medical devices to sporting equipment to wearable technologies to logistics to aviation to the automobile industry, printed electronics are everywhere.

- They say the best technology is the one that feels like it is not present.

- At Protolab, we do exactly that. Moreover, we deploy state of the art printing technology to achieve just that.

- They are everywhere you can imagine.

- On devices you see at your home, shopping mall, car, office, factories, hospital, gyms, amusement park, cafes & more.

- At Protolab, we have successfully manufactured over 1200+ designs of printed electronics for over 50+ large-scale MNCs around the globe.

- Are you looking for a trusted manufacturing partner to meet all your design, technological & quality requirements?

- Our customer relationship champions would be thrilled to talk to you.

Types Of Printed Electronics

Wearables

- Wearable technology with flexible displays & flexible sensors enables devices to conform to our bodies and clothes.

- These devices capture, process & display biometric data from our bodies.

- They also act as a display + control device, allowing us to view notifications, time, control music, etc., by linking to a smartphone.

- The advent of augmented reality & virtual reality is further expanding the horizons for using this technology.

- At Protolab, we manufacture the inner core that empowers these devices and allows them to be compact.

- We manufacture flexible circuits, sensors & motherboards for wearable technology devices.

- These components are thin, light, durable, and designed using visually attractive branding.

- Speak to our design & engineering experts to know how to deliver a world-class solution for you at a great price.

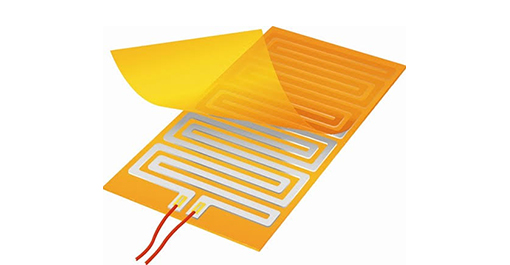

Heaters

- This printed circuit system uses “Positive Temperature Coefficient” ink to generate heat.

- This technology is self-regulating & does not use any wires, making it a safe alternative without fear of overheating.

- They are used in automotive, medical, athletics, aerospace and defense industries.

- We manufacture them using screen-printing technology.

- A substrate is printed with conductive busbars & resistive heating components.

- To safeguard the printed circuit, an insulating layer is applied.

- The insulating layer can be printed with branding images such as logos or operation instructions.

- The final form of the multi-layer heater is then laser or die-cut.

- The heater can be easily mounted in the final installation thanks to an adhesive coating attached to the other side.

- Speak to us today to understand how to manufacture such printed heating devices compatible with your product design.

Sensors

- These devices detect medically relevant parameters from simple physical parameter like blood pressure or temperature.

- These flexible printed devices can be clubbed with biosensors as well.

- They are used to capture different data points that help medical professionals analyze the status of our body functions.

- High‐resolution screen printing of pristine graphene fabricates conductive lines on flexible substrates.

- Well‐defined silicon stencils & viscosity‐controlled inks facilitate the preparation of high‐quality graphene patterns as narrow as 40 μm.

- This technology provides an efficient method to produce highly flexible graphene electrodes for printed electronics.

- They are widely used in various medical devices.

- Protolab is one of the leading manufacturers of flexible sensors in the world.

Applications

Medical

Force sensors

Automotive

NFC / RFID Tags and Antennas

Packaging

Industrial Applications

Healthcare