Membrane keypads are designed in various formats and here we shall elaborate specifically on Flexible Membrane Keypads, Keyboards and Switches.

A Flexible Membrane Switch comprises an array of open momentary contact switches printed with silver conductive paste/ ink on heat-stabilized polyester films treated for adhesion. Design engineering and processes can also be incorporated with SMD LEDs and components, as well as with tactile domes, which are hermetically sealed typically as 5-9 layers membrane keypads and are water-resistant. They can be designed as a matrix or common bus and can be terminated with 0.5 mm, 1 mm, 1.27 mm, and 2.54 mm pitch. They are compatible with ZIF and Female Housings or can be crimped using clincher male/female pins and SIL/ DIL lockable and polarised option housings.

Membrane overlay is created by printing on polyester or polycarbonate films with coloured and conductive inks. The number of layers is increased or decreased depending on the needs or applications, such as tactile or non-tactile, the number of tails, EMI/RFI shielding, overall thickness, etc. The overall thickness of the Membrane switch can be 500 mic-1500 mic or as per customer specification.

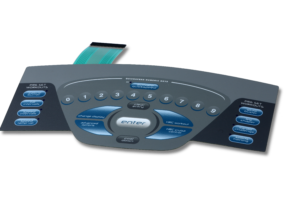

Flexible Membrane Switch Keypad

Protolab HMI’s membrane keypads can incorporate various additional features.

- Chemical & UV resistant materials: For harsh-environment membrane keypads

- Anti-bacterial Polyester film: For Medical or Pharma applications

- Interchangeable legends and inserts: To enable the keypad to be used for multiple purposes.

- Rim, Pad, Braille, 3D types of embossing: To make a keypad more aesthetically pleasing and make it easier for users to find the keys.

- Light Guide Film (LGF) backlighting: Illuminate entire key areas, borders, symbols, logos, or a specific area

- Tactile keys with Metal domes or Poly dome feedback: To provide user feedback on keystrokes

- EMI / RFI shielding: Primarily to enable EMC in electrical devices

- Integrated Flexible Printed Circuits (FPCs) or PCB back panels: According to the user application

- With LEDs, Connectors with 1.27/ 2.54 mm pitch: to incorporate customer feedback

- IP rating up to IP67: Ingress protection

- Steel/Aluminium back panels with mountings

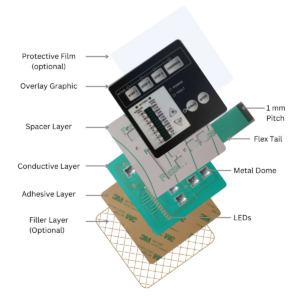

Construction of Tactile Membrane Keypad

Protective Film

The flexible membrane keypad is equipped with a protective film designed to safeguard it from scratches and ensure a pristine, scratch-free surface. This specialized film serves as a protective layer, acting as a barrier against potential damage caused by daily use, handling, or environmental factors. By incorporating this protective film, the flexible membrane keypad maintains its durability and visual integrity over time, ensuring a reliable and long-lasting user experience.

Overlay Film

The top layer is contoured, molded, and sculpted to give the product a third dimension. It is ergonomically improved and aesthetically created to improve the product’s appearance. The printing is carried out on a subsurface using a 125–180 mic. thick film. Based on customer application, Protolab will improve the product by adding the necessary features to the customized product using Colour & Texture, Windows, Dead Front, Embossing, Braille, 3D Effects, Doming, and Interchangeable Legends.

Spacer Layer

The spacer layer comes next, following the overlay layer. This is merely an empty layer, as the name would imply. Separating the overlay layer from the printed circuit layer is what the spacer layer is there for. Because there is more room between these two layers, pressing a key or a legend on the overlay layer will push it into contact with a printed circuit, completing the circuit.

Multi-brand adhesives are a specialty of Protolab. It procures raw materials from the original manufacturers of the leading brands. In order to build spacers and levelling of different thicknesses, such as 88 mic., 225 mic., and 288 mic. thickness, etc.,

Conductive Layer

The printed circuit layer is located beneath the spacer layer. This is the main circuitry that powers the membrane switch. The circuit layer is printed on 125 mic. Polyester material with conductive substrates. connection to the membrane is via an integral extension of the contact layers terminated on crimped Male connectors / Female clincher connectors/ ZIF connectors.

Two contacts are separated from one another in a non-tactile keypad by a laminated spacer. The top contact closes the switch, and the release pressure opens it when the switch is depressed. Top circuit or overlay can be used to describe this layer’s top contact. Again, it depends on the customer because adding extra layers increases their cost.

While in the tactile keypad, metal domes are positioned on top of the circuit contacts on the bottom circuit.

Adhesive Layer:

The adhesive layer is intended to hold the membrane switch in place in the container or product in which it is installed. While the adhesive layer may appear to be insignificant, it is critical to the function and overall performance of a membrane switch. If the incorrect adhesive is used, the membrane switch may pull or break away from the container or product in which it is installed.

Protolab can provide repositionable adhesive, which can be removed and correctly relocated if the user has incorrectly aligned while pasting.

Filler Layer

This is an optional layer added to the membrane based on user requirement, it is also present in some membrane switches. The filler layer serves no functional purpose. It is instead used to “fill” any space around the membrane switch or according to the cabinet grove depth.

Construction of Tactile Membrane Keypad Switch

Standard Construction Layers of Tactile and Non-Tactile Flexible Membrane Keypad

| Sl. No. | CONSTRUCTION LAYERS | Tactile Membrane | Non-Tactile Membrane |

| 1. | Protective Film | Optional | Optional |

| 2. | Graphic Overlay | Yes | Yes |

| 3. | Adhesive | X | Yes |

| 4. | Top Circuit (Conductive Layer) | X | Yes |

| 5. | Metal dome | Yes | X |

| 6. | Spacer | Yes | Yes |

| 7. | Bottom Circuit (Conductive Layer) | Yes | Yes |

| 8. | Rear Adhesive | Yes | Yes |

| 9. | Backing Layer (Optional for leveling) | Optional | Optional |

Protolab stands as a pioneer in the realm of designing and developing flexible membrane keypads. With a commitment to innovation and precision, Protolab has consistently led the way in creating cutting-edge solutions, setting industry standards for the versatility and reliability of membrane keypads. Through years of expertise and a dedication to quality, Protolab continues to be at the forefront of advancing technology in flexible membrane keypad design.

hi!,I like your writing so much! share we be in contact more approximately your article on AOL? I need a specialist in this area to resolve my problem. Maybe that is you! Looking ahead to see you.

Hi, Neat post. There is a problem along with your website in internet explorer, would test this·IE still is the market chief and a good section of other folks will pass over your magnificent writing due to this problem.

This site is incredible. The radiant material shows the administrator’s enthusiasm. I’m dumbfounded and envision more such astonishing substance.

I just could not leave your web site before suggesting that I really enjoyed the standard information a person supply to your visitors? Is gonna be again steadily in order to check up on new posts.

I do not even know how I ended up here but I thought this post was great I dont know who you are but definitely youre going to a famous blogger if you arent already Cheers.

Your blog is so much more than just a collection of posts It’s a community of like-minded individuals spreading optimism and kindness

Just wish to say your article is as surprising The clearness in your post is just cool and i could assume youre an expert on this subject Fine with your permission allow me to grab your RSS feed to keep updated with forthcoming post Thanks a million and please keep up the enjoyable work.

you are in reality a just right webmaster The site loading velocity is incredible It seems that you are doing any unique trick In addition The contents are masterwork you have performed a wonderful task on this topic.

I do believe all the ideas youve presented for your post They are really convincing and will certainly work Nonetheless the posts are too short for novices May just you please lengthen them a little from subsequent time Thanks for the post

I genuinely enjoyed the work you’ve put in here. The outline is refined, your written content stylish, yet you appear to have obtained some apprehension regarding what you wish to deliver thereafter. Assuredly, I will return more frequently, akin to I have almost constantly, provided you maintain this climb.

Stumbling upon this website was such a delightful find. The layout is clean and inviting, making it a pleasure to explore the terrific content. I’m incredibly impressed by the level of effort and passion that clearly goes into maintaining such a valuable online space.