Smart & Durable Membrane Keypads for ICU Beds – Proven Performance by Protolab

Medical beds, especially ICU beds, require highly reliable, user-friendly, and durable control systems. Membrane keypads are an ideal choice for such applications due to their versatility and customisability.

Protolab, a pioneer in manufacturing Medical Equipment Keypads, has been delivering engineering solutions for over 30 years. With a legacy of expertise and innovation, Protolab stands at the forefront of designing and developing advanced Membrane Keypads customised for ICU beds.

-

Common Problems with Membrane Keypads for ICU Beds

- Design & Customization: ICU beds often need specialised layouts, but off-the-shelf Membrane Kypads lack ergonomic and functional customisation to meet user needs.

- Moisture Ingress: Frequent cleaning and high-humidity environments can cause moisture to seep into the keypad, leading to malfunctions or short circuits.

- Exposure to Harsh Cleaning Agents: Regular disinfection with strong chemicals can degrade keypad materials, affecting both appearance and functionality over time.

- Assembly and servicing-related concerns: Improper fitment or complex assembly makes maintenance difficult, increasing downtime and reducing reliability in critical care settings.

- Compatibility and Performance: Inconsistent integration with medical systems can affect responsiveness and reliability.

2. 5 Reasons Protolab Membrane Keypads Are Ideal for ICU Beds

- Custom Design Services: Protolab’s expert engineers work closely with healthcare providers to create ergonomic and intuitive layouts that meet specific requirements and with embedded engineers to optimise the layouts within design guidelines & EMI/ ESD protection.

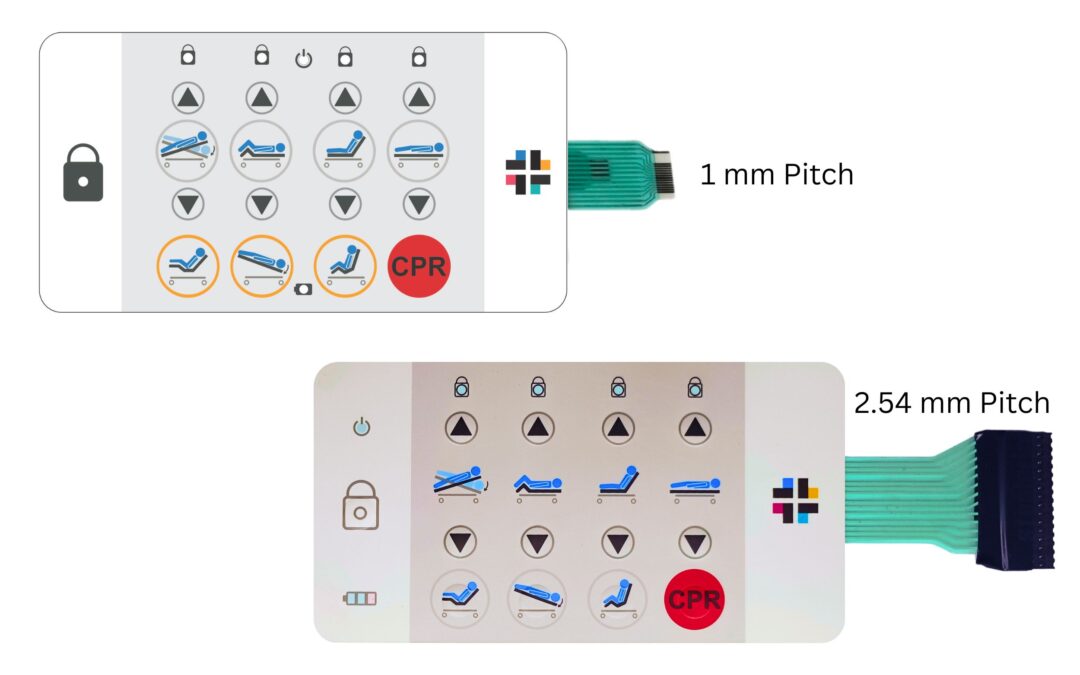

- Tactile and LED Keypads: Features like tactile feedback and LEDs improve usability and ensure precise operation, even in low-light conditions. With profiled flex tails in a single layer with 0.5, 1.00, 1.27, 2.54 mm pitch compatible with ZIF connectors.

- Enhanced Sealing Technology: IP-rated designs to protect against water and dust ingress, ensuring long-term reliability.

- Chemical-Resistant Coatings: Special coatings to withstand exposure to harsh disinfectants without compromising functionality or aesthetics.

- Design engineered: For adaptability, compatibility and extended performance.

3. Essential Functions for ICU Bed Membrane Keypads

- Head Position Adjustment: Controls for raising or lowering the headrest for patient comfort and medical procedures.

- Leg Position Adjustment: Allows the caregiver to modify the angle of the leg section.

- Height Adjustment: Enables raising or lowering the entire bed for better accessibility and ergonomic care.

- Trendelenburg/Reverse Trendelenburg Positions: Facilitates advanced positioning for critical care and recovery.

- Lock/Unlock Controls: Ensures the safety of settings by preventing unintentional changes.

- Electronic Controls (with or without Remote Handsets): Integrated controls for Nurse or patient to adjust bed positions with precision.

- CPR Function (Manual or Electric): One-touch flattening and firm surface support for emergency CPR procedures.

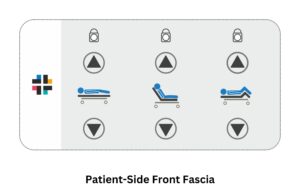

Dual-Sided Interface Design for ICU Beds

4. Benefits of Protolab Membrane Keypads

- Patient Safety: Reliable adjustments ensure optimal patient positioning and minimise risks.

- Reliability: Long-lasting performance, even under demanding medical conditions.

- Enhanced Usability: Intuitive designs with clear icons and tactile responses streamline caregiver operations.

- Ease of Maintenance: Designed for easy cleaning and resistance to wear, reducing downtime.

- Cost-Effectiveness: Durable construction reduces replacement frequency and overall maintenance costs.

Your blog is a testament to your dedication to your craft. Your commitment to excellence is evident in every aspect of your writing. Thank you for being such a positive influence in the online community.

Your writing is a true testament to your expertise and dedication to your craft. I’m continually impressed by the depth of your knowledge and the clarity of your explanations. Keep up the phenomenal work!

Hey there You have done a fantastic job I will certainly digg it and personally recommend to my friends Im confident theyll be benefited from this site

Your blog is a testament to your passion for your subject matter. Your enthusiasm is infectious, and it’s clear that you put your heart and soul into every post. Keep up the fantastic work!

Every time I visit your website, I’m greeted with thought-provoking content and impeccable writing. You truly have a gift for articulating complex ideas in a clear and engaging manner.

This web site is really a walk-through for all of the info you wanted about this and didn’t know who to ask. Glimpse here, and you’ll definitely discover it.