The Chemistry Behind Printed Electronics in Biomedical Devices

In modern Medical Electronics, the convergence of chemistry and engineering is driving a transformation. Printed electronics are now powering biomedical devices that are Lightweight, Flexible, and Patient-friendly.

Whether it’s a Wearable Biosensor, a Smart Bandage, or a Membrane Keypad on a Medical Device — the true magic lies in the Functional Inks that bring these circuits to life.

-

Silver Conductive Inks – The Nerve Pathways of Electronics

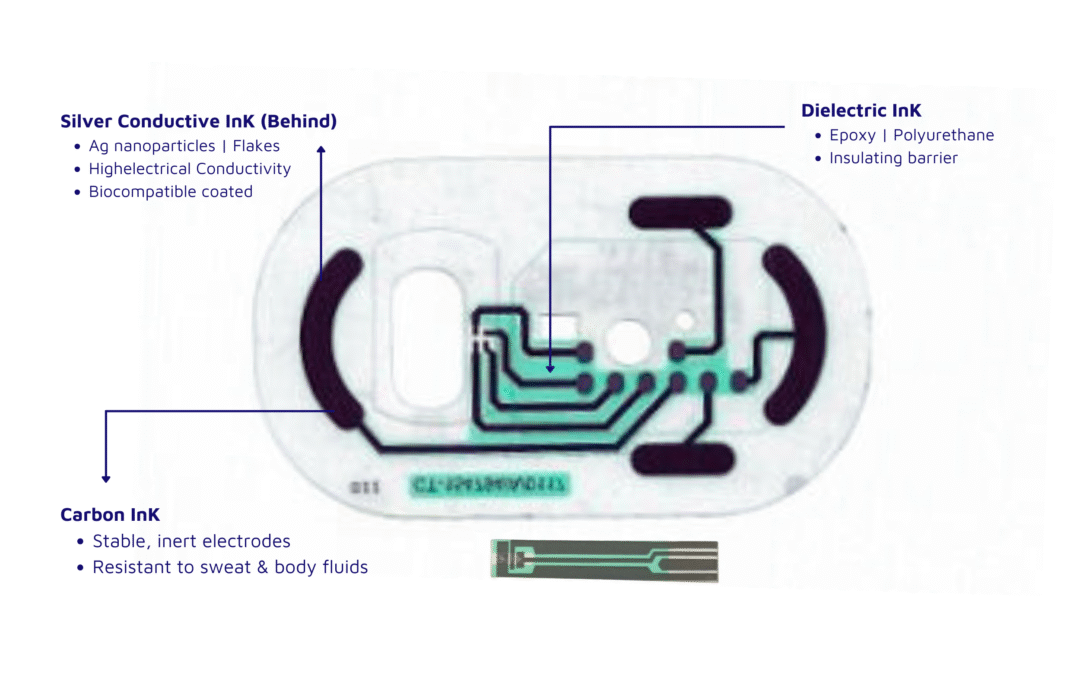

Conductive inks serve as the tracks of Printed Electronics, carrying electrical signals and power seamlessly across flexible substrates such as PET, TPU, or Polyimide films.

Common Conductive Materials:

- Silver Ink (Ag): Highly conductive, corrosion-resistant, and ideal for Biosensors and ECG/EEG Electrodes.

- Carbon Ink (C): Flexible, stable, and cost-effective for circuits exposed to bending or chemicals.

- Dielectric (Polymer Insulation): Used alongside conductive inks to define circuits, control pathways, and protect sensitive areas.

Chemical Insight:

Conductive inks are formulated with Metallic Nanoparticles dispersed in a polymer matrix. Upon curing, the solvent evaporates, and the metallic particles form a continuous conductive network. The polymer binder adds adhesion, stretchability, and biocompatibility, ensuring the circuit can bend and flex without cracking.

-

Dielectric Inks – The Shield of Printed Electronics

Dielectric inks are essential in biomedical printed circuits, acting as electrical insulators between conductive layers or traces. They protect circuits from short circuits, electrical leakage, and chemical damage caused by cleaning agents or body fluids.

Chemical Composition:

Dielectric inks are typically based on UV-curable polymers, epoxy resins, or polyurethanes, designed to create smooth, pinhole-free layers.

Their performance depends on:

- High dielectric strength to insulate voltage differences

- Excellent adhesion to flexible substrates like PET or TPU

- Resistance to humidity, disinfectants, and mechanical stress

In Biomedical Applications:

Dielectric inks form the protective backbone of Printed Biosensors, Wearable Health Patches, and Medical Membrane Switches, where patient safety and signal reliability are crucial.

-

Carbon Inks – The Durable Surface Layer

Carbon inks are used as protective and resistive layers over conductive traces. They enhance the longevity and reliability of Medical Circuits such as ICU Bed Keypads, Sensor Electrodes, and Touch Switches.

Why Carbon Matters:

- Prevents silver migration in humid or ion-rich environments

- Increases switch life cycle and abrasion resistance

- Provides chemical stability against cleaning agents

Chemistry Insight:

Carbon inks are made with graphite flakes or carbon black dispersed in a thermosetting resin binder. The particle concentration and binder chemistry define the ink’s resistance value, which can be tailored for sensors or control interfaces.

Screen Printed Electrodes on TPU Material

-

Adhesion, Flexibility & Biocompatibility

For biomedical devices, biocompatibility is as important as performance. Inks must remain safe for skin contact and resistant to body fluids, disinfectants, and mechanical stress.

Key Formulation Elements:

- Plasticizers to maintain flexibility under repeated bending

- Crosslinking agents that improve adhesion and environmental stability

This chemistry ensures that flexible circuits continue to perform flawlessly, even after multiple sterilization cycles.

-

Resistance to Harsh Environments

In hospital and clinical environments, devices face harsh sterilization and cleaning. Inks must endure:

- Alcohol-based cleaning solutions

- UV or gamma sterilization

- Humidity and body sweat exposure

By optimizing polymer crosslinking density and nanoparticle dispersion, engineers achieve exceptional ink durability without sacrificing flexibility or conductivity.

Conclusion: Chemistry That Cares

Every ink layer in Biomedical Printed Electronics plays a unique chemical role — conducting, insulating, or protecting. Together, they form circuits that are as smart and reliable as the devices they power.

Beyond just performance, these inks enable innovative device designs — from ultra-thin wearable sensors to Flexible Medical Membranes that conform to the human body. By carefully engineering the chemistry of conductive, dielectric, and carbon inks, manufacturers can achieve precision, longevity, and biocompatibility in ways traditional electronics cannot.

At Protolab, we continue to push the boundaries of Printed Electronics for Healthcare, creating custom Circuits and Keypads that meet the highest standards of safety, durability, and functionality, shaping the future of smart, patient-friendly medical devices.

Recent Comments